BMW will use hemp flooring for 2022 car show displays.

We’ve heard of hemp concrete and hemp insulation. Not to mention the possibility of binding plywood with hemp-derived pectins, and the reasons hemp fiber trumps wood fiber.

But could hemp actually out-wood wood?

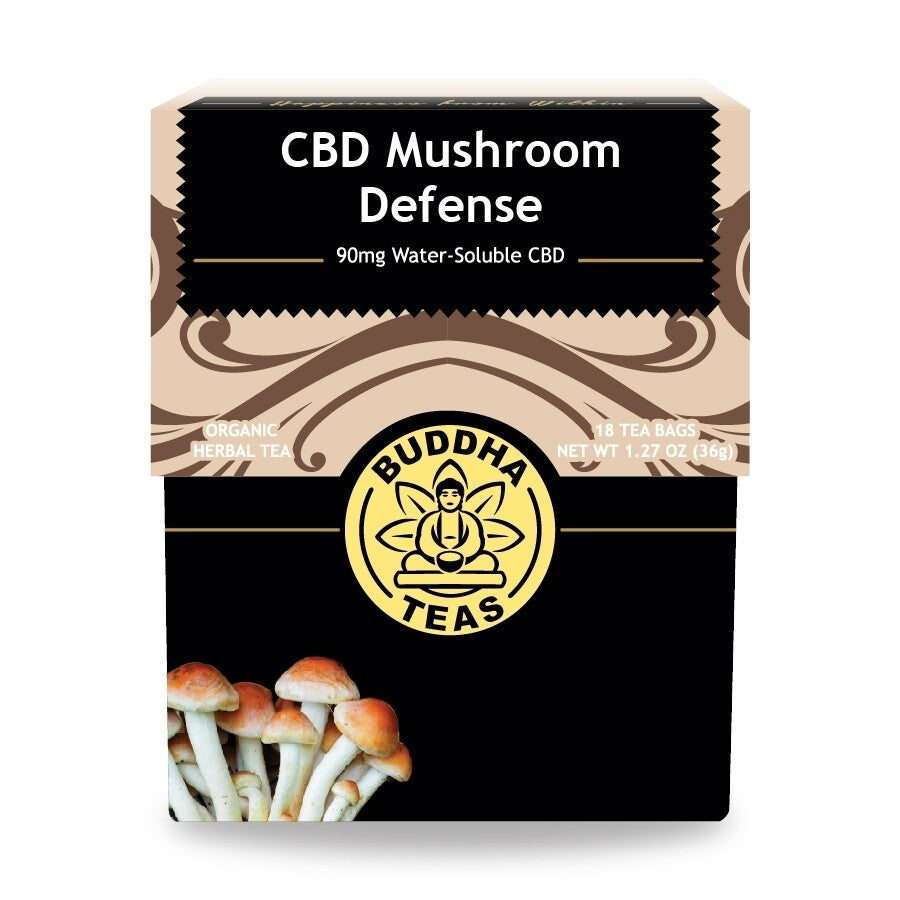

A company called HempWood thinks it can. In fact, they see hemp-based wood as an answer to the risks of over harvesting and deforestation. The Kentucky-based manufacturer is challenging the lumber industry with a pressed-hemp hardwood that can be used for flooring, tables and cabinets.

“HempWood was developed to mimic the hardness, density and stability of oak, a popular building material,” writes Nicole Stempak for Hemp Grower. “The [parent company's] team studied the process used to create popular bamboo flooring to develop a similar, but stronger, wood-like product from the hemp plant.”

Pressed at high heat, the resulting product is actually 20 percent denser than oak, HempWood founder Greg Wilson told Hemp Grower.

German car maker BMW has offered a vote of confidence, ordering 450 square feet of HempWood on which to display its 2022 auto collection at car exhibits.

German car maker BMW has offered a vote of confidence, ordering 450 square feet of HempWood on which to display its 2022 auto collection at car exhibits.

And Architect Magazine recently suggested that hemp-based hardwoods can hold its own in the lumber industry: “[W]ith faster cultivation rates, a higher carbon capture, and advances in processing, hemp could be the next big thing in structural systems after mass timber.”

Hemp has a few things going in its favor in terms of sustainability:

- Acre for acre, hemp stores carbon at a higher rate than trees

- Hemp can be grown and harvested twice a year, rather than once a decade or even once a century

- Replacing hardwoods with pressed-hemp hardwood could help prevent over harvesting and deforestation

“Until recently, hemp has remained a peripheral product — the most familiar of which is Hempcrete — in the construction industry,” Blaine Brownell wrote for Architect Magazine. “However, it is becoming an increasingly viable option for more common building elements due to developments related to its similarities to — and differences from — wood.”

What about exteriors? The product is being sold for interior, non-structural use like flooring, counter tops, accent walls and furniture. That said, the company hasn’t ruled out the potential for exterior use in the future, writing on its website, “We do not currently make any exterior or structural products. Not because they don’t perform, but because we focus on interior face grade.”

And then there’s price. During the pandemic, having just opened for sales at in the fourth quarter of 2019, HempWood leadership turned its attention to automating processes and updating equipment. As a result the company was able to scale production and bring prices down.

“The spike in lumber prices [over the past year] made us at or below the cost of comparative domestic hardwoods,” HempWood founder Greg Wilson told HempBuildMag.

So, can hemp out-wood wood? Not yet.

Hemp building supplies are demonstrating several economic and environmental advantages over wood and other products. As for structural and exterior use, it remains too soon to tell. But product testing and technological advances may make such uses economically feasible in the future.

The possibilities are promising for the hemp industry — and for a greener construction industry too.

“In theory,” Brownell wrote for Architect, “if enough new structures are built with hemp instead of concrete, steel, or timber, the construction industry could shift dramatically toward net-zero carbon.”